I’m often asked: What’s the difference between a field overhauled turbocharger and a factory-rebuilt turbocharger? Aside from the fact that the “factory rebuild” can only be done at the Hartzell Engine Technologies facility in Montgomery, AL, there are a number of key differences. First, by definition a rebuilt item must meet new part standards, so overhaul limits and practices will not apply.

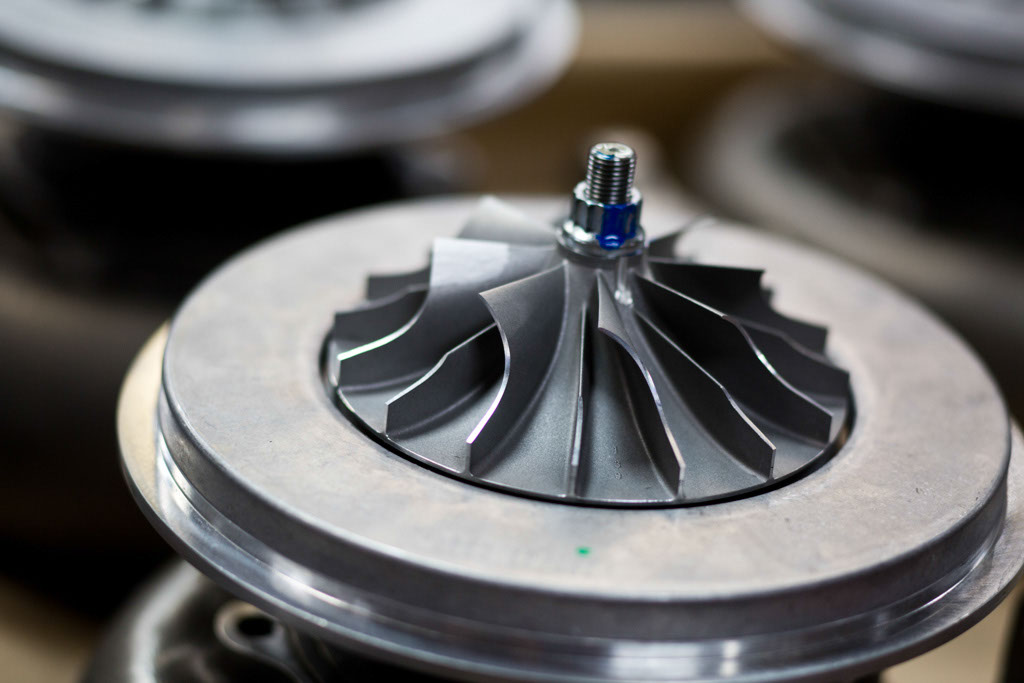

Secondly, aside from being inspected and rebuilt by the folks who built it new in the first place, the rotating group, or CHRAs (Center Housing Rotating Assembly) that come through our process have the added – and significant – benefit of being run on our state-of-the-art Schenck TBsonio high-speed balancer, just like our factory new aircraft turbochargers. We are the only company in aviation with this capability.

The TBsonio is an amazing machine. We routinely balance our turbo cores at speeds starting at 50,000 rpm and go up to 108,000 rpm. Yes, that’s one-hundred-and-eight-thousand revolutions per minute! That’s about 40-times faster than your aircraft’s engine is turning at cruise. While that may seem excessive, that’s the speed range our turbochargers typically operate in. The result is a finished assembly that has been operationally tested and precision balanced.

Sure, a field overhauler might balance the compressor and turbine wheels individually during the process, but without high-speed dynamic balancing of the completed rotating assembly you can’t really say the unit is “balanced.” Operating the CHRA at high-speed during the balancing process also helps verify the unit was assembled correctly. Would you really want an under-tested unit on your airplane, or worse, one that hasn’t been tested at all?

You might ask, if other shops don’t bother with the added balancing steps, why does HET? Think of it this way: Your car tires typically rotate at around 1,000 rpm. If you’ve ever felt a tire that’s out of balance, imagine what it would be like at 100 times that speed! At 108,000 rpm, even the smallest unbalances cause pronounced vibrations, which can manifest themselves in a lot of ways, from noise to placing a great deal of stress on the bearings. And when it comes to high-speed bearings, added stress shortens reliability and operational life.

We’ve made a significant investment in the TBsonio balancing system and it’s paying off. We are able to provide our customers with a new or factory rebuilt turbo that’s been tested under oil pressure at speeds from 50,000 to 108,000 rpm.

That’s just one more way we can assure that our aircraft turbochargers are the best they can be as we continue to improve on the performance, reliability and value of every product we make.

You can see the TBsonio balancing machine in action in the video below.